Core Drilling innovators

We have taken an analytical approach to fully understand the core drilling process. Without a doubt the biggest impact on PRODUCTIVITY, PROFITABILITYY, SAFETY and EMISSIONS is the unproductive inner tube cycle.

As a result of realizing the magnitude of potential that drilling longer core runs can bring, we are today designing and testing technologies to enable this to become a reality.

Imagine how a 20% plus productivity gain would impact your drilling program!

About Us

Based in New Zealand but with a global outlook, we understand the challenges faced by the drilling industry in trying to achieve greater efficiencies while minimizing environmental impacts.

Our technologies are designed to dramatically improve the productivity, profitability and safety while reducing emissions.

We believe that our solutions will help to drive a more sustainable future for the industry, and we are excited to be at the forefront of this important work.

Our Why

As exploration holes get deeper the percentage of time drilling gets less and wireline trips get longer, negatively impacting efficiencies.

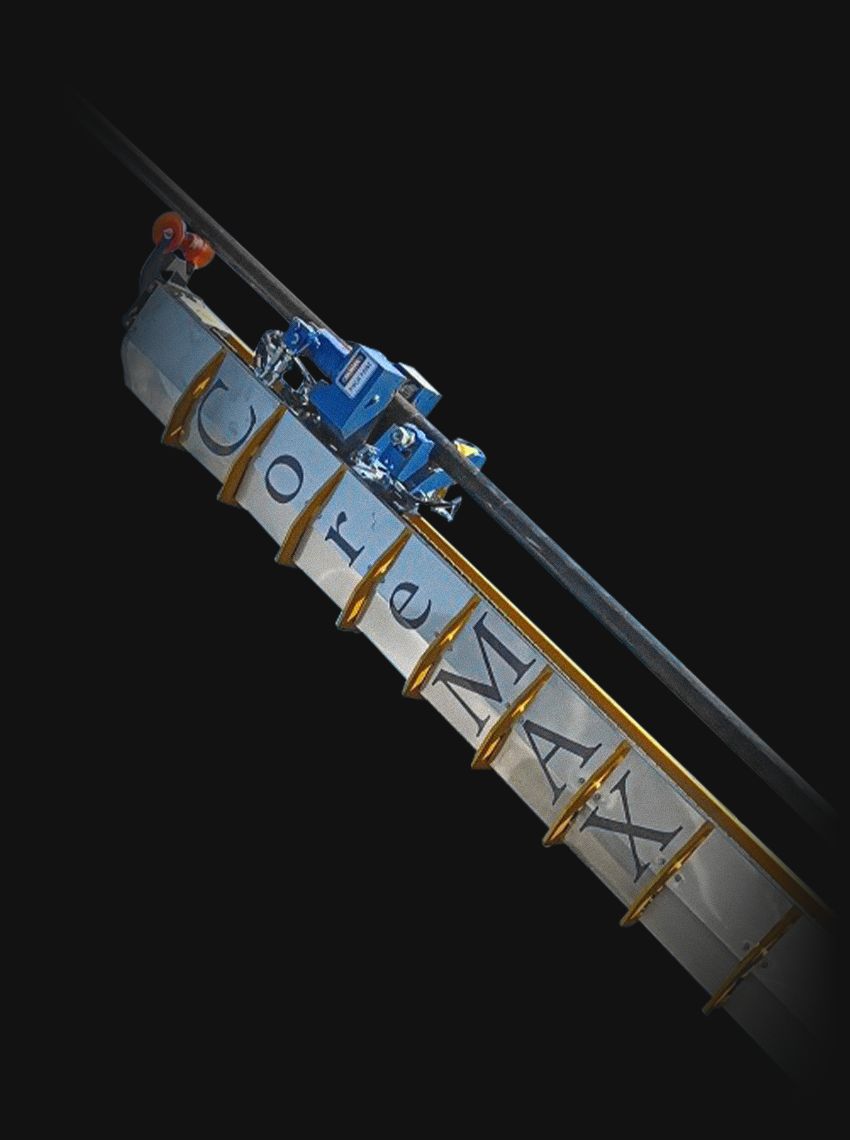

CoreMAX technologies work to offset this non-productive time by allowing significantly longer core runs to be drilled.

CoreMAX’s Patent Pending technologies are specifically designed to allow you to drill longer core runs regardless of the rig’s mast length – or underground spatial limits – safely while maintaining core orientation.

Technology that fits any drill rig

On our very first day field testing our CoreMAX handler we increased our client’s average production from 16 meters per shift, – and beat their record 30 meters for a shift, with a total of 44 meters of core drilled.

And this was while we were learning to operate our prototype!